BALLI CYCLE

From staple to fabric, our in-house production cycle.

Starting with the staple, passing through carding or combing, continuing with spinning and warping to weaving and finishing. Our Bally Cycle unites all individual production steps in-house in a vertical cycle that transforms raw material into finished fabric.

RAW MATERIAL

It represents the start of the entire production cycle. In this first phase we select the raw material for our creations.

We work with suppliers who meet strict criteria: certified and traceable breeders who comply with European social, environmental and animal welfare regulations.

REGENERATED

A large part of our raw material comes from regenerated textile waste, obtained from old garments or leftover fabrics. The operators manually select the rags most suitable for recycling, sort them by colour and fray them into fibres ready to be processed again. This allows us to reduce waste and valorise materials that would otherwise be lost.

PREPARING VIRGIN WOOL

The virgin 'raw' wool undergoes an initial washing to remove residual impurities.

Once dried, we proceed to carding, a process that reorders and combs the fibres, making them manageable for the next steps.

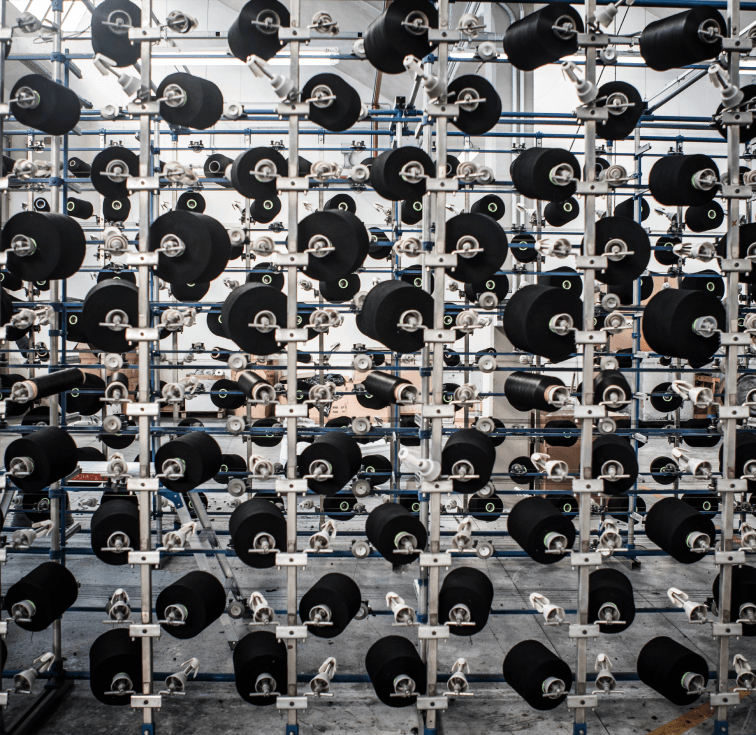

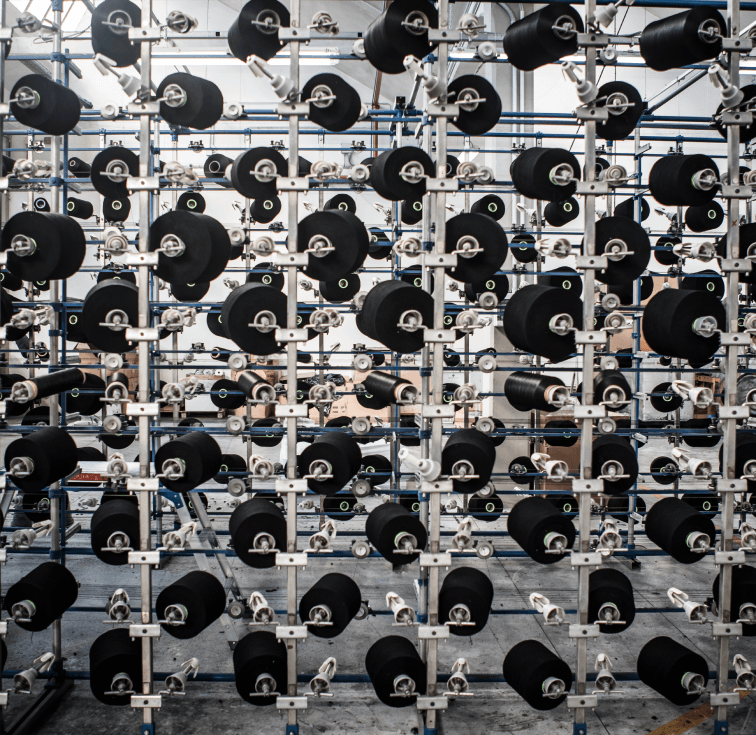

CARDING AND SPINNING

In spinning, we card the raw material to transform it into yarn. During this process we unravel, clean and align the fibres, preparing the wool until a carded yarn is obtained. Once the yarn is obtained, we wind it onto a spindle or bobbin, ready for the next stages of processing.

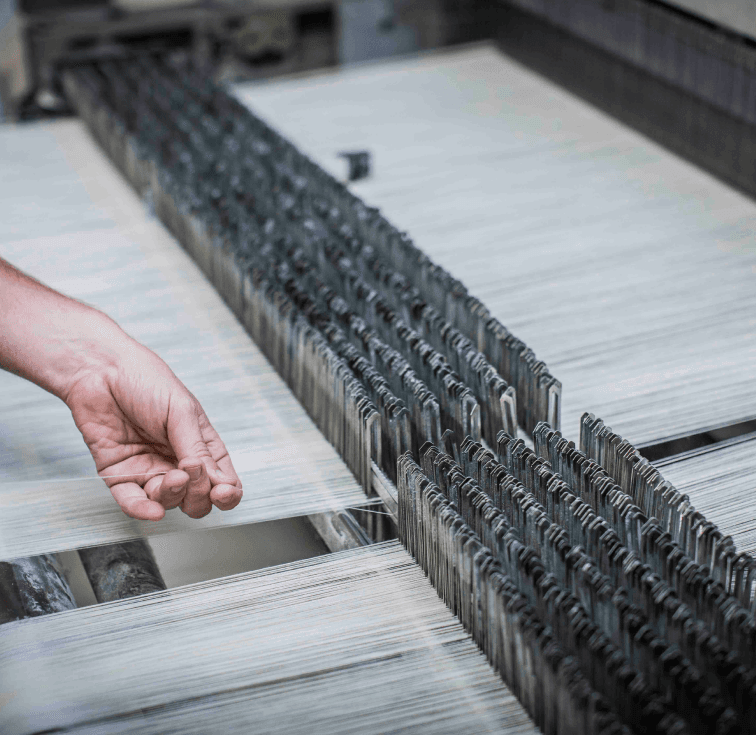

WARPING

At this stage we prepare the warp for the looms, sorting the threads according to specific patterns that influence the design of the finished fabric.

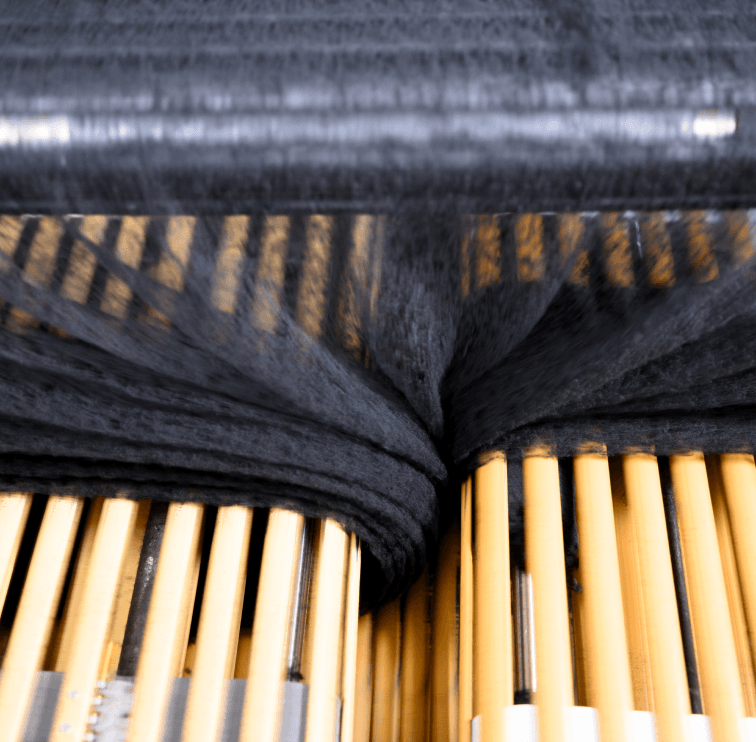

WEAVING

Weaving is the moment when we transform yarn into fabric. The looms, guided by our weavers, skilfully interweave the warp and weft threads according to a studied arrangement. This stage is crucial to obtain the fabric with the desired characteristics in terms of design and strength. For this reason, we perform continuous quality checks throughout the weaving process.

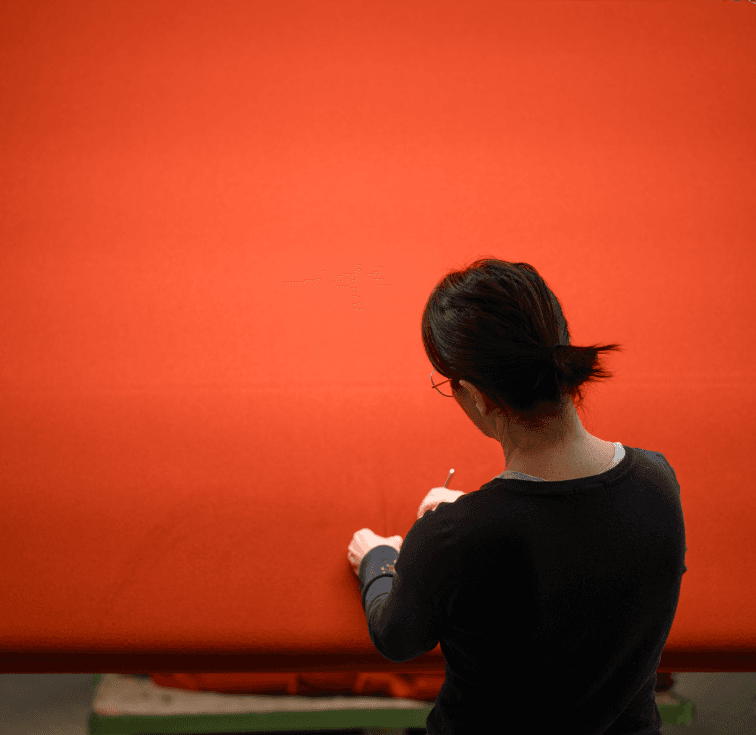

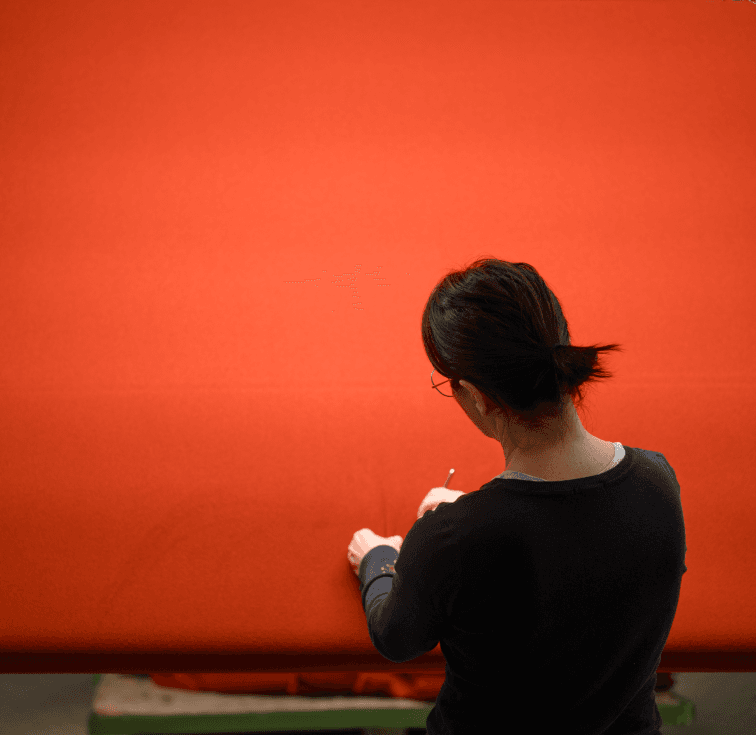

CONTROL AND MENDING

The unbleached fabric, fresh from the weaving mill, is ready for the first inspection stage. At this stage we inspect every detail for any defects in weight or length. If necessary we proceed with darning, a process dedicated to correcting imperfections.

FINISHING

FULLING

Finishing is the beating heart of our production cycle, the phase that gives real character to our creations. Here we treat the fabrics by combining different finishing techniques depending on the texture and the desired effect.

Among the main finishing steps is fulling, a mechanical process that ennobles the raw materials within the fabric structure.

FINISHING

DYEING

The dyeing process gives the fabric the colouring desired by the customer. It is not applied to all fabrics, but only to 'piece-dyed' fabrics, i.e. fabrics where the dyeing takes place at a later stage, and not from the individual yarn.

This process produces a uniform and intense colouring, which is ideal for plain fabrics, which require a homogeneous shade over the entire surface. In contrast, fancy or 'yarn-dyed' fabrics obtain their shades by mixing yarns of different colours.

FINISHING

FINAL FINISHING

The final finishing step is finishing: depending on the desired process, the final characteristics of the structure and fabric such as softness, appearance and touch are enhanced.

MIRROR CONTROL

The final, meticulous check on the fabric. The mirror control consists of an extremely precise check, carried out by hand by our operators. With this timeless and historical process, we check that every detail of the fabric meets our quality standards.

Now we can say the fabric is ready.

SAMPLER

In this space we set up the collections and colour cards manually, and prepare the sending of prototypes and flags to our customers.

Every order is carefully checked and processed.

FINISHED WAREHOUSING AND SHIPPING

In this department we assign the finished fabrics to each customer's order, which is then taken over by the logistics department and shipped. There is then the final qualitative and quantitative check, to ensure that every detail of the order is strictly adhered to.

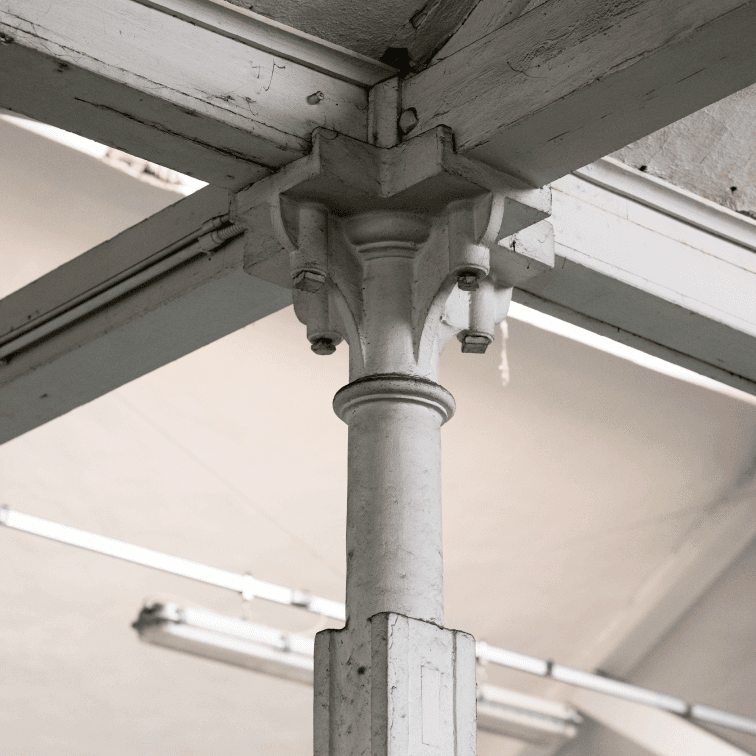

SHOWROOM

Among the most precious rooms of our Fabbricone, our Showroom preserves Guido Dolci's frescoes that frame our latest collections. We dedicate this space to welcoming partners and customers visiting our premises.

COMMERCIAL OFFICE

The various members of our sales team are the face of the company worldwide. They take care of our customer relations and order updates, operating within walking distance of the production areas.

Our creative process offers endless possibilities

Find out which

Would you like to know more about our Fabbricone Storico?

The tour begins